Maximum efficiency and precision with the professional tool from FlexArm

Thanks to its precise mobility robust construction and ergonomic design, it is the ideal solution for carrying out grinding work more efficiently and ergonomically in toolmaking and other metalworking operations. Whether for large workpieces or in hard-to-reach areas – the grinding arm enables you to achieve consistently high-quality surface finishing with minimum effort.

Increase productivity and quality in your business and optimise your processes with the grinding arm – your solution for reliable results and more efficient production.

Find out more about these professional tools now and take your production to the next level!

All FlexArm DIE GRINDING ARM advantages at one glance:

Relieving & ergonomic

Relief for the operator, _as he takes over the weight and handling. This makes work easier and less strenuous.

Precise & movable

The grinding arm can be precisely controlled. This makes it easy to reach hard-to-access areas or complicated surfaces. The result is better, and waste is reduced.

Timesaving & efficient

Thanks to the easy-to-use design, grinding tasks to be completed faster, work processes are streamlined, and production times are reduced.

Robust & durable

Made from high-quality materials _and designed for continuous industrial use. Long service life and low maintenance requirements.

Variants of FlexArm DIE GRINDING ARM

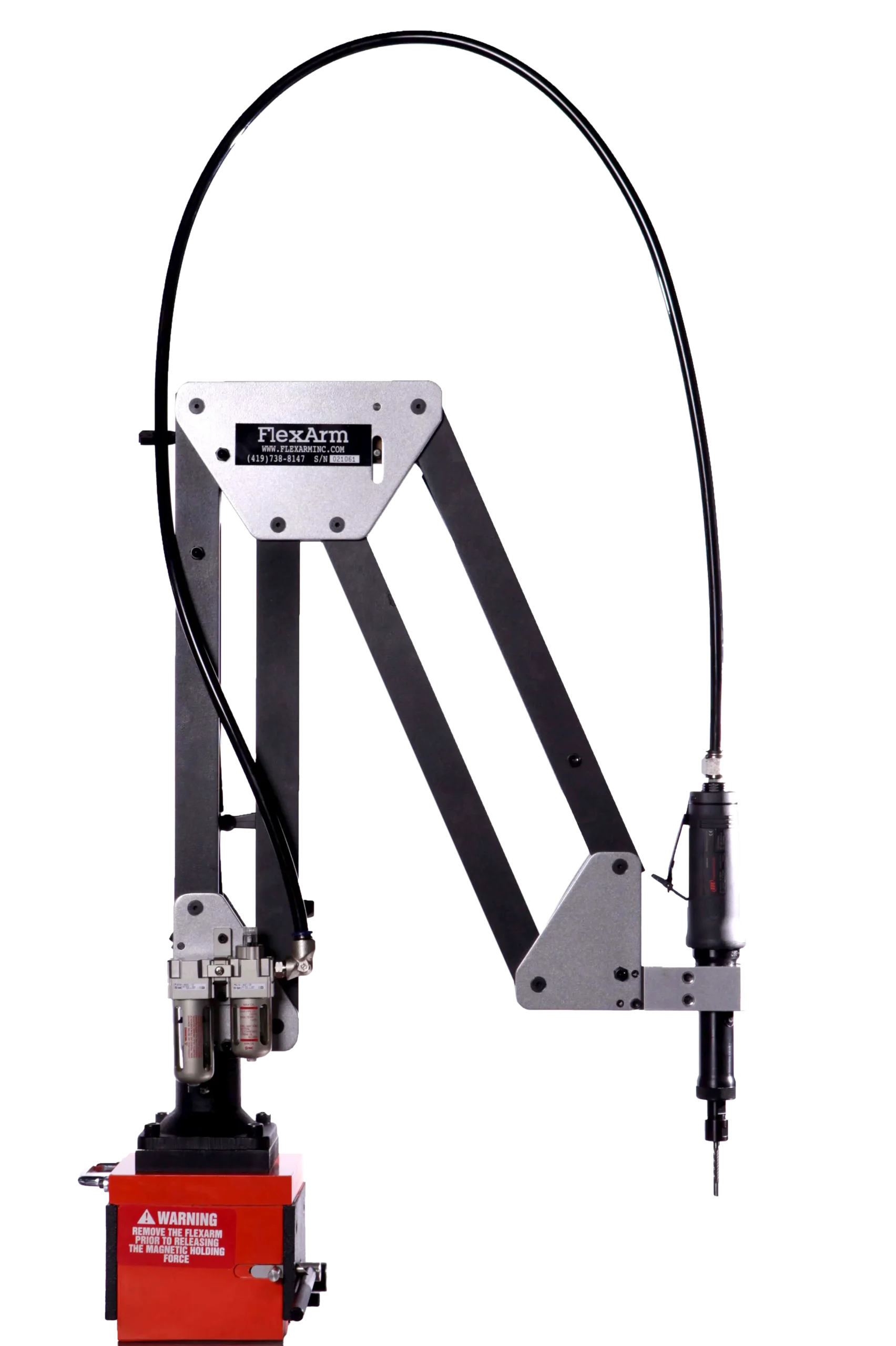

With the FlexArm die grinding arm for mould repairs, you can carry out precise ginding work at a perfect angle and significantly reduce repair times. Thanks to the practical magnetic base, the FlexArm can be securely attached to any metal surface and is ready for use in no time at all.

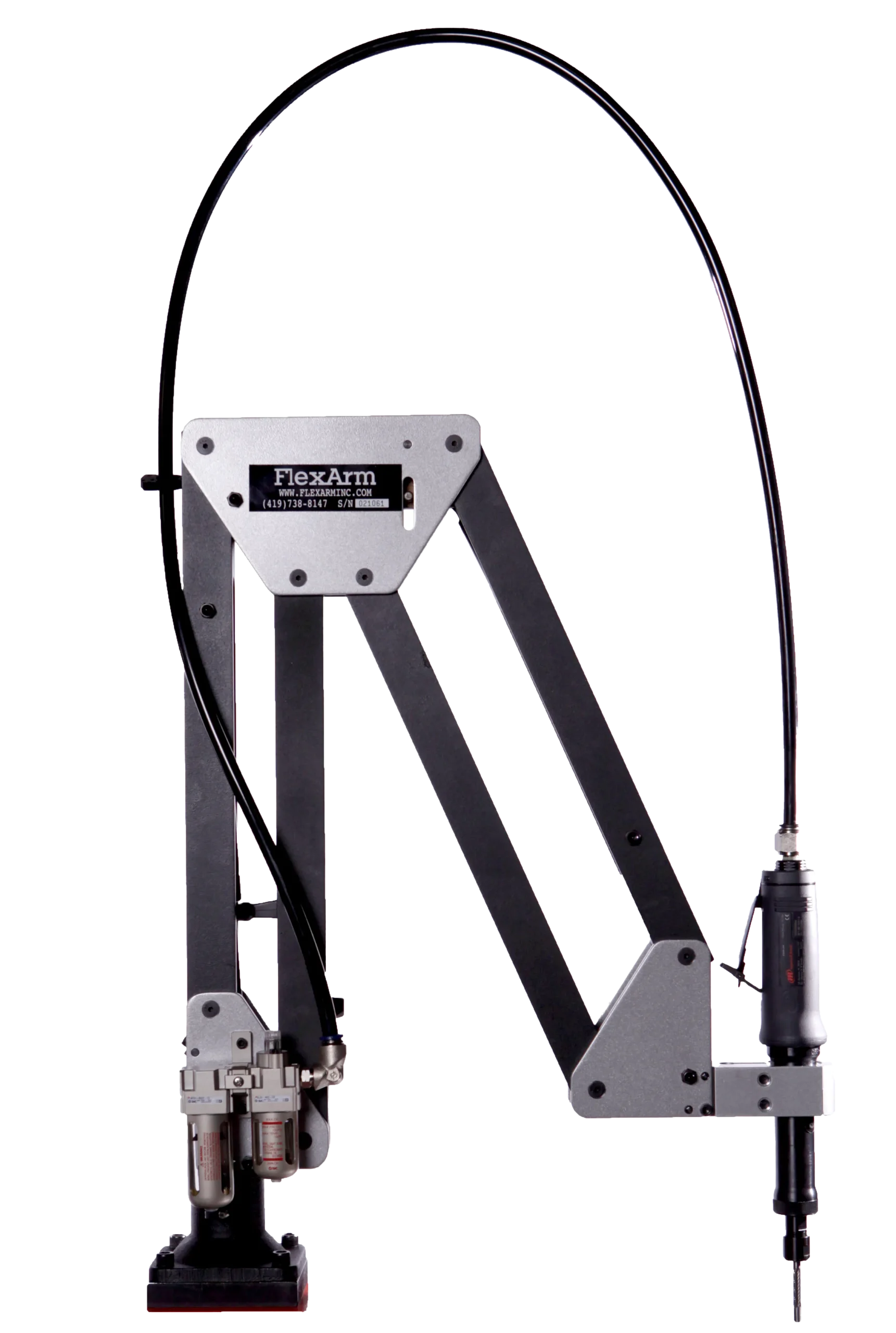

The FlexArm with flange base is a special mounting variant with a permanently stable and secure mounting option. The flange base enables even greater stability and precision, especially for work that requires high torques or repetitive movements.

Do you have any questions about the optimum configuration, selecting the right FlexArm size or the suitability of the model for your specific requirements? Our experienced team is always available for personalised advice. Feel free to contact us to find the perfect solution for your needs!

DIE GRINDING ARM in two sizes (S-36, M-60):

Ergonomics and versatility for demanding tasks

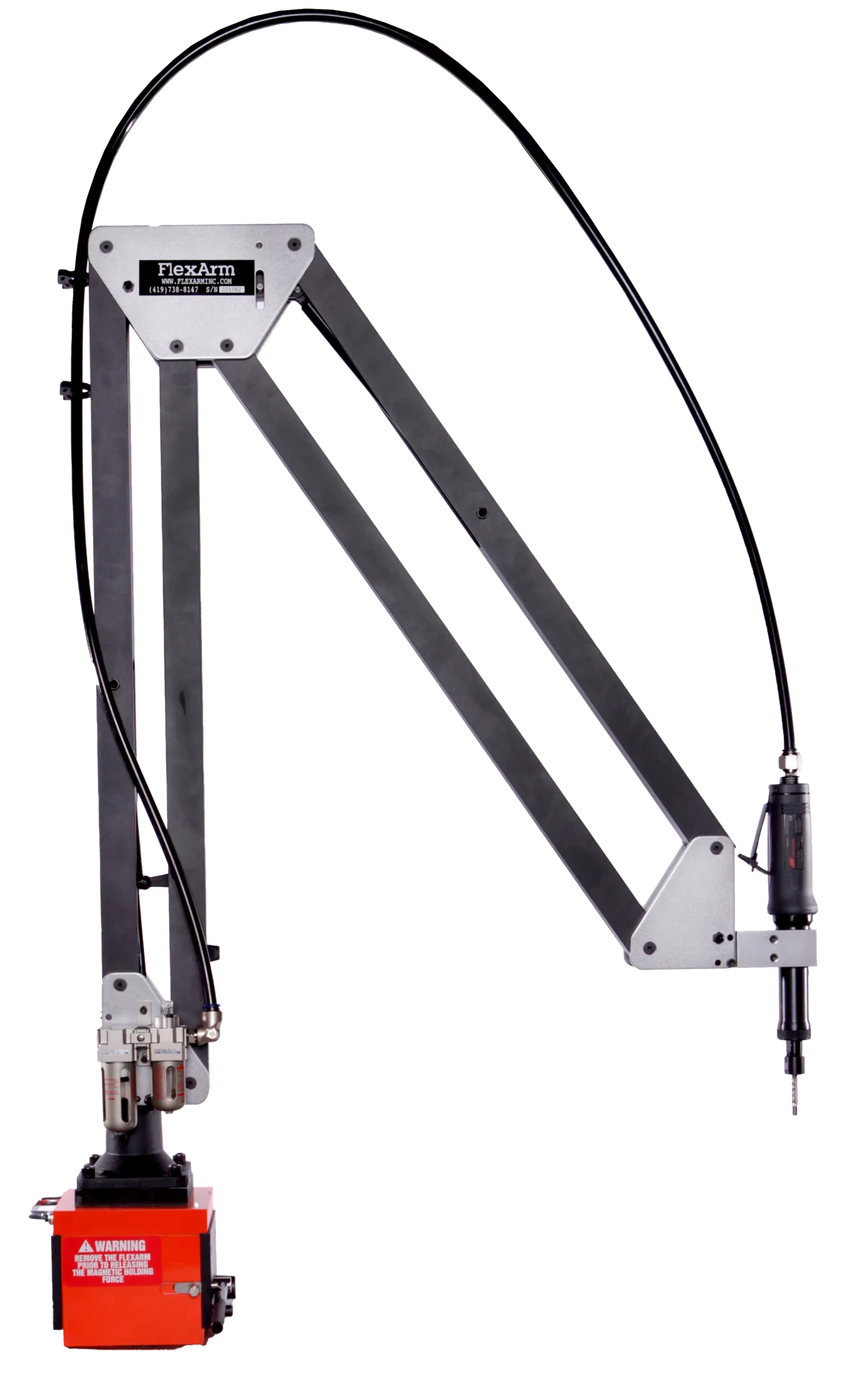

The FlexArm die grinding arm is available in two sizes to cover different requirements: The S-36 impresses with its ergonomics and versatility and is ideal for precise applications that require flexible adjustment. The M-60, on the other hand, offers maximum performance and robustness for industrial grinding and polishing work, even under demanding conditions. Both variants are designed for efficiency and durability.

Suitable accessories

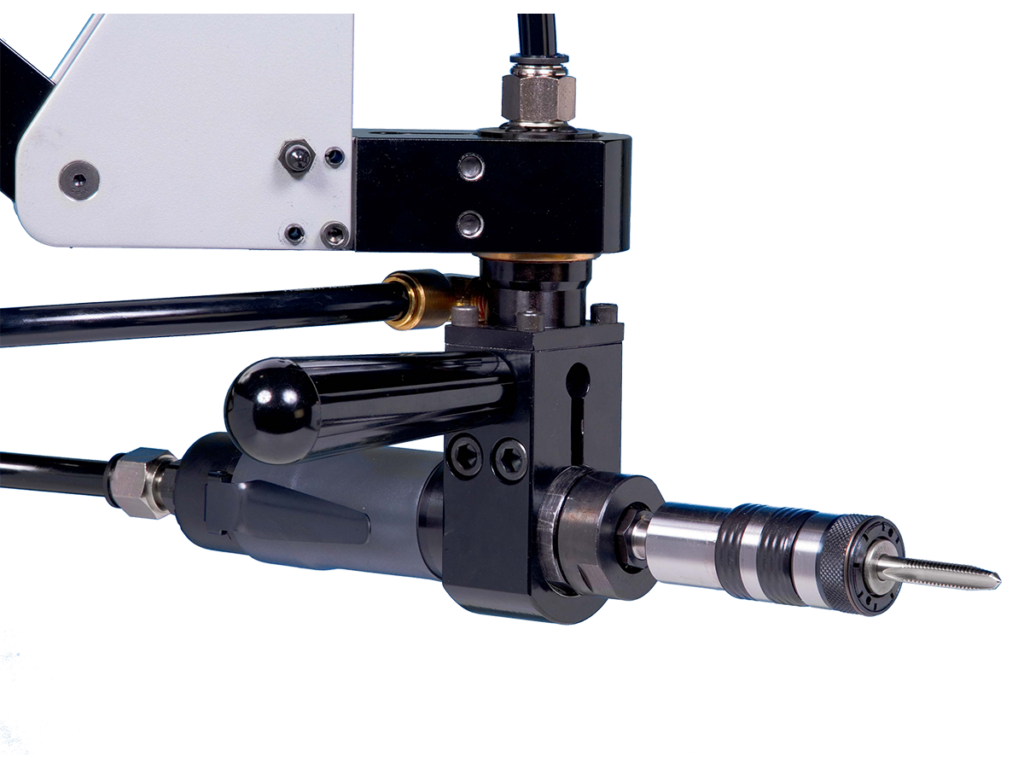

The Horizontal Die Grinding Adapter allows the FlexArm to be brought into a horizontal position for efficient and precise machining of hard-to-reach areas and complex workpieces. The Magnetic Base Mount ensures maximum flexibility, as the FlexArm can be quickly and securely attached to any metal surface and easily moved if required.

The collets ensure that the tools used are held securely and enable quick tool changes, which increases efficiency for different grinding jobs. The grinding pin in various shapes also ensure the necessary precision and adaptability to optimally process different materials and surfaces.

Contact us, we have the right accessories for your requirements!